During the past few years, the finfoil program hasn’t always been getting the attention it deserves. Apart from a few minor public updates, most progress has been happening privately in my garage. In 2020 this will change!

Full time commitment

Starting in April 2020, I’ll be finally committing full time to finfoil. I resigned from my day job to dedicate at least a year towards finfoil in order to explore it’s full potential.

For this I need your help! Your input will be vital to influence which features are getting developed first and to grow the community that will make finfoil support your fin building for the years to come.

Further down this post, you’ll find a brief overview of the features that have been worked on and you might expect to hit finfoil in 2020.

Free credits

Subscribe to the mailchimp newsletter below to show your support, we’ll be handing out free credits through this list. Upon subscription, you’ll also receive a link to help testing our new v1.2 release!

What to expect in 2020

- YouTube channel

- Fin panel placement

- Low budget High tech

- CNC g-code & machining

- Professional partnerships

YouTube channel

As fin building is a very specialised activity, just providing the software still leaves many aspiring fin builders with questions. A YouTube channel containing tutorials and fin physics will help the community grow and truly make fin building available to shapers of all kind.

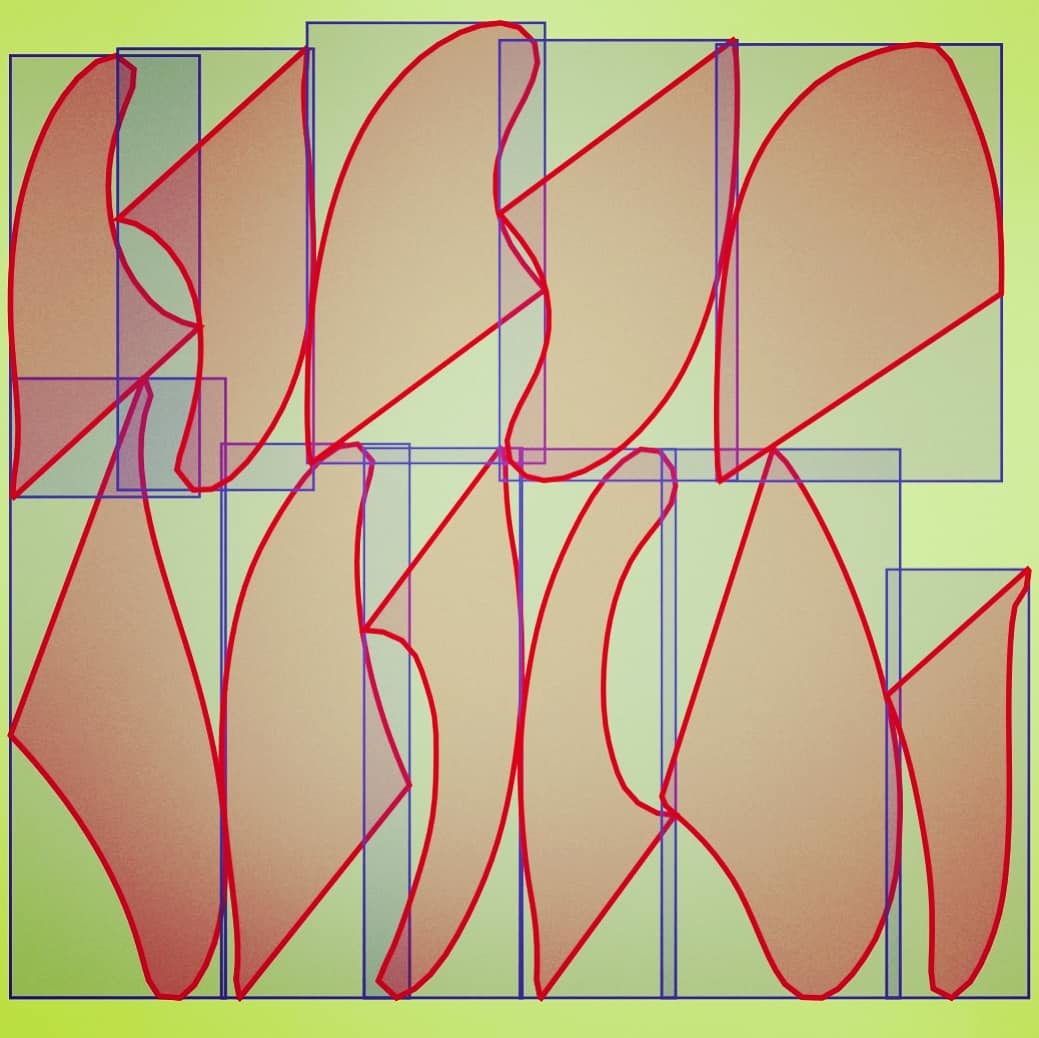

Fin panel placement

Maximising the fins produced from of your expensive or labour intensive fin panels is not an easy job. We’ve been experimenting with algorithms that are fast and effective increasing your fin output and reducing waste. The same algorithms can be deployed to maximise the output (minimise waste) of your expensive high tech fibres, while taking into account your desired fibre orientations for optimal stiffness and fin flex patterns.

Don’t forget to subscribe to the newsletter to show your interest and to stay up to date about these features.

Low budget, high tech

In order to achieve high tech surf fin quality, expensive investments are typically advised. However, through some clever use of cheaply available tools and software generated templates, very accurate and high quality fins can be built requiring minimal investment. Although though they would definitely speed up the process, there is no need to invest in expensive CNC equipment or high tech vacuum lamination systems.

Don’t forget to subscribe to the newsletter to show your interest and to stay up to date about these features.

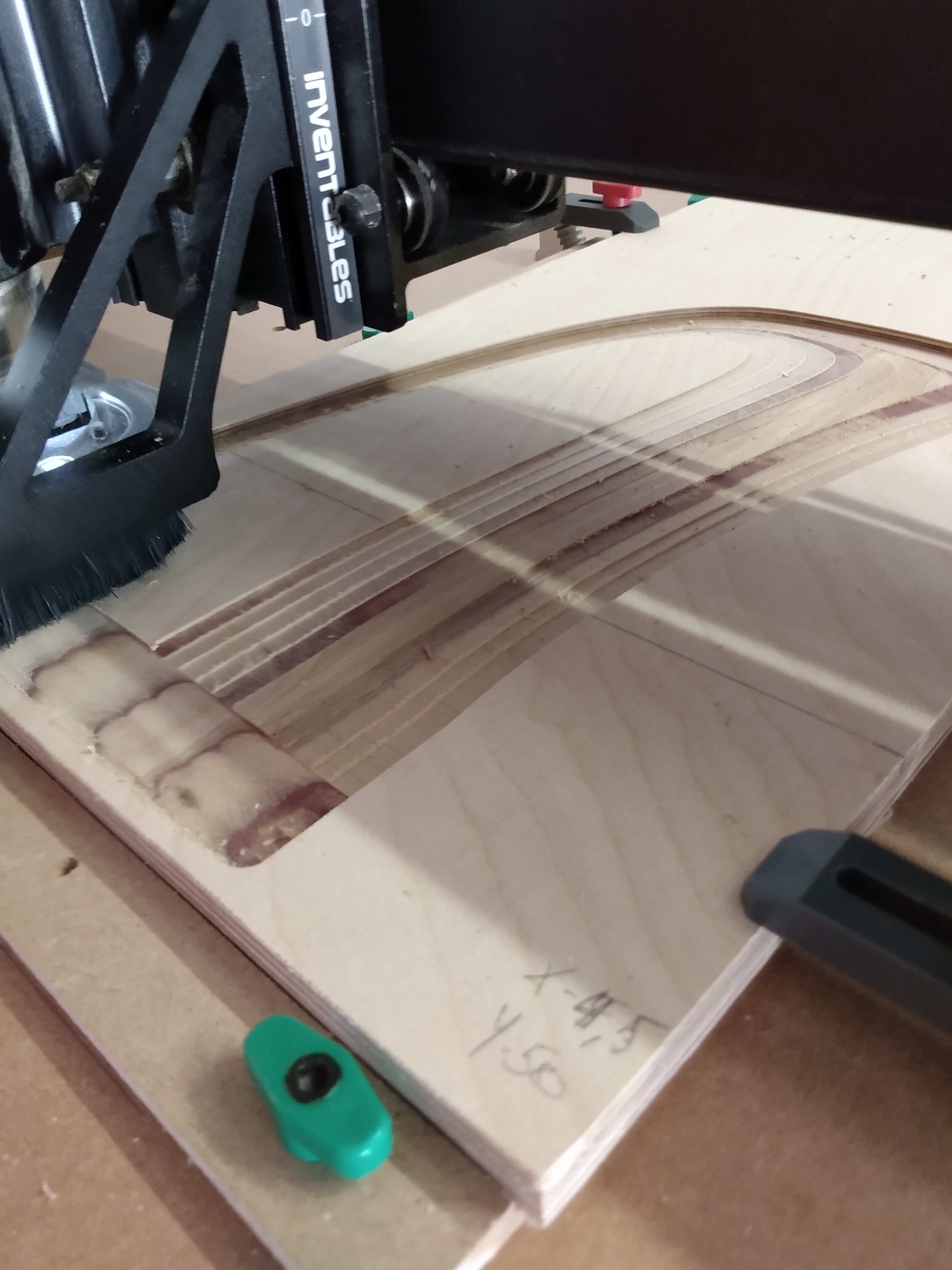

CNC g-code & machining

Commercial CNC CAM software can be hard to get started with and even harder to optimise for production. Bit sizes, roughing strategy, finishing tolerance and other CAM settings have major impact on the speed and quality of the finished fin.

Finfoil simplifies and reduces the choices to make and uses toolpath strategies optimised for machining foils, achieving speeds and surface qualities surpassing many commercial packages.

Don’t forget to subscribe to the newsletter to show your interest and to stay up to date about these features.

Professional partnerships

Are you a professional fin builder or CNC machine manufacturer? 2020 is the year to grow your business by partnering with finfoil. 3D web previews to show of your designs in your website or full integration of the CAD/CAM features with your CNC machines, let’s discuss how we can make your business grow!

Get in contact through info@finfoil.io or subscribe to the newsletter to show your interest and to stay up to date about these features.